FRQ of EDM

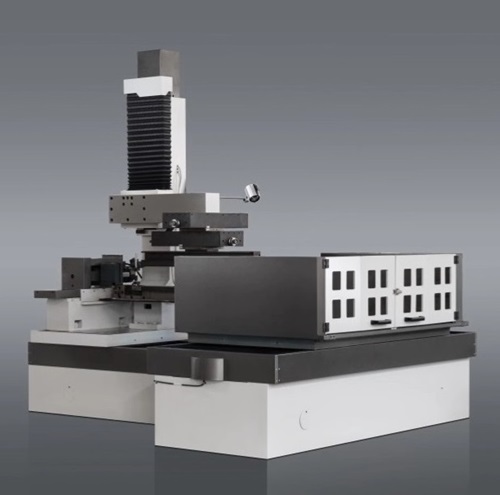

What are the advantages of the Wire cut EDM machine?

Wire EDM (Electrical Discharge Machining) machines offer several advantages, making them a popular choice for precision machining applications:

High Precision: Wire EDM can achieve extremely tight tolerances, typically within ±0.005 mm (0.0002 inches) or even tighter, allowing for the production of highly precise components with intricate geometries.

Complex Shapes: Wire EDM is capable of cutting complex shapes and profiles that may be difficult or impossible to achieve with conventional machining methods. This includes internal corners, sharp angles, and intricate contours.

No Contact Cutting: Unlike traditional machining methods like milling or turning, wire EDM is a non-contact process. This means there is no physical contact between the cutting tool (the wire) and the workpiece, resulting in minimal mechanical stress and no tool wear.

Versatility: Wire EDM can be used to machine a wide range of electrically conductive materials, including metals such as steel, aluminum, titanium, and alloys, as well as conductive ceramics and some advanced composite materials.

Minimal Material Waste: Wire EDM produces very little material waste since the cutting process is accomplished by electrical discharges eroding the workpiece material. This makes it a cost-effective solution, especially for expensive materials.

Surface Finish: Wire EDM can achieve excellent surface finishes, often eliminating the need for secondary finishing operations such as grinding or polishing.

Automation and Efficiency: Modern wire EDM machines often feature advanced automation capabilities, including CNC control and programmable operations, allowing for high levels of productivity and efficiency.

No Cutting Forces: Since wire EDM is a non-contact process, there are no cutting forces applied to the workpiece, reducing the risk of distortion or deformation of delicate or thin-walled parts.

Overall, wire EDM machines offer high precision, versatility, and efficiency, making them suitable for a wide range of applications in industries such as aerospace, automotive, medical, electronics, and tool and die making.

For anything about wire cut EDM machines, please feel free to contact us.

Suzhou Worthy Intelligent Equipment Co., Ltd

Add: Room 301, building 2, No. 38, Yaofeng Road, Jinqiao Development Zone, Mudu Town, Wuzhong District, Suzhou. PO: 215101

Tel: +86-512-68782578

Email: sales@worthycnc.com

Bob@worthycnc.com

edmachining@hotmail.com

Whats App: +86-13338697597

Wechat: Boblee56

RELATED NEWS

- How to choose electrodes for your EDM machines? Graphite Electrodes or Copper El 2025-08-25

- What are the advantages and disadvantages of the Wire EDM machines? 2024-10-14

- Why do Clients give THUMBS-UP to our drilling EDM and electrical discharge sawin 2024-07-08

- Comparing between EDS and Band Saw 2024-07-08

- FAQ about EDS (Electrical discharge sawing) machine 2024-07-01

Categories

Latest News

Contact Us

Contact: Mr.Bob Li

Phone: +86-13338697597

E-mail: sales@worthycnc.com

Whatsapp:+86-13338697597

Add: Room 301, Building 2, No. 38, Yaofeng Road, Jinqiao Development Zone, Mudu Town, Wuzhong District, Suzhou. PO: 215101