CNC Diamond Wheel Dressing machine

CNC Diamond Wheel Dressing machine

This Dressing machine is primarily for dressing synthetic diamond grinding wheels on high-speed steel wire/rod roll ring grinders, using Electrical Discharge Machining principles.

CNC Diamond Wheel Dressing machine

I. The benefits you can get with our EDM machines:

1. You'll be able to sharpen your diamond grinding wheel with ease;

2. It'll give your diamond grinding wheel a sharper edge, improved precision, and enhanced dependability;

3. Operating the machine is very easy.

II. Function:

This unique device is primarily for dressing synthetic diamond grinding wheels on high-speed steel wire/rod roll ring grinders, using Electrical Discharge Machining principles.

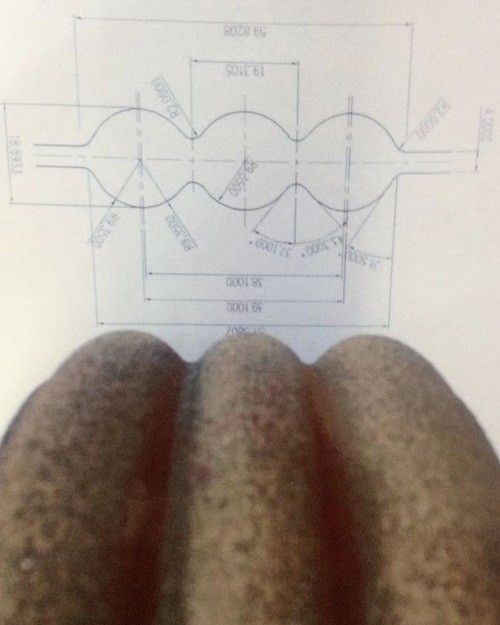

We've developed two types of CNC machines for dressing R-sharp or V-sharp grooves on high-speed steel wire/rod tungsten carbide roll rings: a CNC diamond wheel dressing machine and a CNC carbide grinder.

First off, this machine lathes the electrode wheel, which can be either graphite or copper.

Secondly, the diamond wheel is dressed with the electrode wheel adopting the principle of the EDM.

Thirdly, the tungsten carbide roll is grinded with the diamond grinding wheel on the CNC carbide grinder.

III. Machine Features:

1. Totally closed electronic control integrated design;

2. Patented operating system;

3. Separate turning and EDM setups;

4. Automatic tool setup and centering for both turning and EDM;

5. Submerged type EDM process;

6. EDM adaptive trimming;

7. Fire detection system;

8. Works with shaped cutters or regular turning tools.

IV. Machine Features:

1. Totally closed electronic control integrated design;

2. Patented operating system;

3. Separate turning and EDM setups;

4. Automatic tool setup and centering for both turning and EDM;

5. Submerged type EDM process;

6. EDM adaptive trimming;

7. Fire detection system;

8. Works with shaped cutters or regular turning tools.

V. Advantages:

1. The human impact is minimal, making it easy to operate;

2. The dressed diamond wheel has a higher accuracy and better reliability;

3. The dressed diamond wheel boasts superior precision and reliability;

4. The dressed diamond grinding wheel maintains shape accuracy and good durability;

5. The machine is user friendly and has a longer usage life.

VI . Specification:

Specification | ||

Diamond Wheel Dressing machine | Model | TD01CNC |

X/Y axis travel | mm | 250*220 |

X/Y axis resolution | mm | 0.001 |

Diameter of diamond grinding wheel | mm | Ø40- Ø400 |

Diameter of electrode wheel | Ø160- Ø320 | |

Width of repairable diamond wheel | mm | 80 |

Electrode wheel processing method | * | Turning/Lathing |

Type of repairable diamond wheel groove | * | any type |

Programming | * | G code/CAD |

Positioning method | * | Auto tool setting/ auto centering |

Working liquid tank | mm | 780*750*300 |

Repetitive positioning accuracy | mm | 0.01 |

Electrode loss rate | % | 0.2 |

Efficiency | mm3/min | 400 |

Working fluid | * | EDM fluid |

Machine size (L* W * H) | mm | 1750 * 1550 * 2200 |

Machine weight | KG | 2500 |

Power | KW | 6 |

Processing accuracy: | ||

Cylindrical deviation of out circle | mm | 0.01 |

Outer diameter tolerance | mm | ±0.01 |

Hole diameter tolerance | mm | ±0.01 |

Hole depth tolerance | mm | ±0.005 |

The best surface roughness for grinding | um | Ra≤0.4 |

Position center tolerance of roll ring face | mm | ±0.01 |

VII. Evidences:

1. The machine has won national patents, the Ministry of Machinery Technology Progress Award, and the certificate of high-tech products.

2. The machines are used in many high speed steel wire/rod plants in China, such as Shenyang high speed steel wire plant, Pan steel plant, Bao steel plant, Great wall steel plant, Qiqihar steel, etc.

The machines are popular in both China and overseas markets like Thailand, Vietnam, Iran, Malaysia, Philippines, Nigeria, etc.

INQUIRY

Categories

- CNC EDM Sawing Machines

- CNC Drilling EDM Machines

- CNC Wire EDM Machines

- CNC Sinker EDM Machines

- CNC Milling Engraving Machine

- CNC Diamond Wheel Dressers

- CNC Carbide Grinders

- CNC Electrochemical Deburring Machines

- Parts of CNC EDM Sawing Machines

- Parts of CNC Drilling EDM Machines

- Parts of CNC Wire EDM Machines

- Parts of CNC Sinker EDM Machines

- Parts of CNC Milling Engraving Machines

- Other Materials and Tools

Latest News

Contact Us

Contact: Mr.Bob Li

Phone: +86-13338697597

E-mail: sales@worthycnc.com

Whatsapp:+86-13338697597

Add: Room 301, Building 2, No. 38, Yaofeng Road, Jinqiao Development Zone, Mudu Town, Wuzhong District, Suzhou. PO: 215101