CNC Sinker EDM Machines

CNC Sinker EDM Machines

CNC Sinker EDM Machines are mainly used for the Die mould making with a good surfance finish.

CNC Sinker EDM Machines

I. Benefits you can get with our CNC Sinker EDM Machines

1. You can improve machining efficiency with our CNC sinker EDM machine.

Its max machining speed is: 400mm3/min with 50A current; and 800mm3/min with 100A current (above TR850CNC).

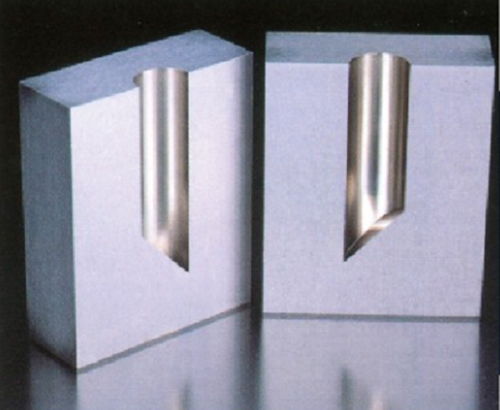

2. You can improve the machining surface finish.

The best roughness you can get with our sinker EDM machine is 0.2um.

3. You can save machine tools cost.

The sinker EDM machine we make is 50%lower than overseas brand machines.

II. Features of CNC Sinker EDM Machines

1. Heavy duty casting (Applying the resin sand method to remove the internal stress. and the weight of the machine is 10% more than otherChinamanufacturers);

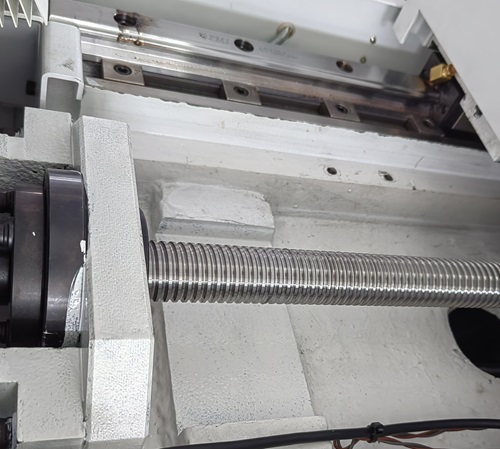

2. The machine is equipped with C3 class ball screw and linear guide ways imported from Taiwan;

3. The machine body cast is one whole structure which is more stable, and the positioning accuracy is 50%-70% higher than China standard( 9 points checked on the worktable surface);

4. 2 times higher oil output pump than other competitors.( Dia100mm oil tubes);

5. 3-5 pieces of oil sucking pipes to ensure the machining oil or door opening.

6. New designed filtration system (bigger filter or 6 pcs filters), to ensure the clear and fast oil output;

7. Up-down type oil tank door, which is easy for operators to open or close the door with just two fingers.

8. All oil tubes are higher pressure type tubes;

9.Central lubrication system for moving part.( Just once in one month to lubricate it.)

10. The machine can meet the Korean market clients.

III. Advantages of CNC Sinker EDM Machines

1. LCD touch screen display and input;

2. X.Y.Z three-axis linkage function;

3. Ultra precision machining PIKA circuit - mirror machining function;

4. Expert processing technology database:

The system is equipped with a rich process software database, multiple combinations of electrodes and workpieces, and can perform automatic and manual processing of various materials; Specially designed for the processing of certain special materials, we provide users with a wide range of choices, such as processing hard alloy materials, high-temperature alloy materials, titanium alloy materials, and power supplies with strong targeting. The processing surface has a small metamorphic layer and a small impact on surface hardness (HRC).

5. Precise circuit board design

The discharge control board adopts a highly integrated design, which consolidates the original four boards into one board and has CAN communication function. The data signal is processed through onboard high-speed microcontroller and CPLD chip, and the mainstream all optical coupling isolation design greatly improves the anti-interference and stability of the system.

6 AUTO processing functions:

Input machining information such as electrode and workpiece materials, machining area, electrode scaling amount, and final machining surface roughness. The system automatically calculates machining parameters based on the expert machining process database and completes the entire process from rough machining to precision machining;

7 Automatic positioning function:

It has the functions of end face positioning, angle positioning, column center positioning, hole center positioning, arbitrary three-point circle center positioning, and discharge position alignment positioning. At the same time, the automatic positioning function can be used to measure and correct the processed workpiece online;

8 Automatic arc cleaning circuit:

Real time monitoring of machining gap conditions during discharge machining. In case of minor short circuits and arc pulling, an alarm will be triggered and arc cleaning measures will be taken in a timely manner;

9. Liquid level control, liquid temperature control, automatic fire extinguishing device, etc., ensure the safety of machine tool operation. When the working fluid temperature reaches 60 degrees Celsius, the machining will automatically stop. When the liquid level is lower than the necessary height for machining, the machining will not be executed.

10. Power outage reset, contact perception and other functions:

The machine tool can remember the coordinate values of the current coordinate system, and in case of sudden power outages or other emergencies, it can still find the set coordinate points after restarting; In addition, there are functions such as contact perception, diagnosis, and error message prompts. When there is an operation error or malfunction, there are alarm and error message prompts to guide the operator to refer to the manual and troubleshoot.

11. Diverse processing modes

12. Rich CNC swing functions

While the spindle is in servo motion, the other two axes can be combined into different trajectory shaking motion modes based on the shape of the electrodes, achieving intermediate and fine trimming of the cavity sidewalls. The shaking function is combined with the high-speed tool lifting (AJC) function, and its movement promotes chip removal, allowing for stable processing even without flushing. The powerful Loran function, through the use of LN and LP parameter settings, enables separate processing of shaking actions in different quadrants, providing different shaking methods.

IV. Main specification

Parameters / Model | TR450CNC | TR540CNC | TR650CNC | TR850CNC | TR1260CNC | TR2180CNC (2 heads ) |

X*Y*Z Travel (mm) | 450×350×300 | 500X400X300 | 650*450*400 | 800*500*400 | 1200*600*500 | 1500*800*600 |

Working table L*W (mm) | 700×400 | 750X450 | 900*600 | 1100×600 | 1250×800 | 2500*1200 |

Max electrode weight (Kg) | 100 | 120 | 150 | 200 | 200 | 300 |

Machine load (kg) | 1000 | 1800 | 2500 | 3000 | 4500 | 8000 |

Distance between electrode and working table (mm) | 320-620 | 400-700 | 400-800 | 500-900 | 500-1000 | 750-1350 |

Size of oil reservoir (mm) | 1080×700×450 | 1440X800X500 | 1650×950×550 | 1800×1100×570 | 2100×1250×620 | 3500×1800×800 |

Machine weight (kg) | 2500 | 3300 | 3500 | 4500 | 6500 | 16000 |

V. Pictures of our sinker EDM machine:

INQUIRY

Categories

- CNC EDM Sawing Machines

- CNC Drilling EDM Machines

- CNC Wire EDM Machines

- CNC Sinker EDM Machines

- CNC Milling Engraving Machine

- CNC Diamond Wheel Dressers

- CNC Carbide Grinders

- CNC Electrochemical Deburring Machines

- Parts of CNC EDM Sawing Machines

- Parts of CNC Drilling EDM Machines

- Parts of CNC Wire EDM Machines

- Parts of CNC Sinker EDM Machines

- Parts of CNC Milling Engraving Machines

- Other Materials and Tools

Latest News

Contact Us

Contact: Mr.Bob Li

Phone: +86-13338697597

E-mail: sales@worthycnc.com

Whatsapp:+86-13338697597

Add: Room 301, Building 2, No. 38, Yaofeng Road, Jinqiao Development Zone, Mudu Town, Wuzhong District, Suzhou. PO: 215101