CNC Wire Cut EDM Machines

CNC Wire Cut EDM Machines

CNC Wire Cut EDM Machines are mainly used for the metal conductive workpieces cutting, such as die molds, precision parts, etc.

CNC Wire Cut EDM Machines

I. Benefits you can get with our EDM Wire Cut Machines:

1. You can cut larger type dies molds with a taper angle: +/-30 degrees at a better accuracy.

The max x/y/z travel of the wire cut EDM machine we make is 2000mm*3000mm*1000mm, and the max taper angle is +/-30 degrees and its cutting accuracy is 0.01mm. It is difficult for the low-speed brass wire EDM machine to cut the larger jobs. If your jobs do not request a special accuracy, our wire EDM machine is quite suitable for your jobs.

2. You can save the wire EDM machine cost greatly.

The wire EDM machine cost is around 1/3 of the similar type brass wire EDM machine. If your jobs are larger, like auto die molds, home application jobs molds, which do not require a special higher accuracy, the molybdenum wire EDM machine we make is a good choice for you.

3. You can save consumable part EDM wire cost greatly.

The electrode wire material is molybdenum with our wire EDM machine. And the molybdenum wire can be used repeatedly, comparing the one time cutting brass wire to be through away. So its main consumable wire cost is lower than the brass wire type EDM machine: around 20% of brass wire EDM machine; Molybdenum wire is reusable and it can be used for 4-5 days/each time.

II. Features of Wire Cut EDM Machines (WEDM)

1. The wire cut EDM machine we make can cut all metal jobs with a good surface finish, such as high-temperature heat-resistant alloys, high chromium, high nickel alloy, titanium alloy.

2. The types of wire cut EDM machine we make are various, from320*400*500mm to 2000mm/3000mm/1000mm are available.

3. The wire cut EDM machine can cut a job with a max tape of +/-30 degrees.

III. Advantages of Wire Cut EDM Machines (WEDM)

1. Super high cutting speed: Max :200mm2/min;

2. The cutting accuracy on our wire cut EDM machine is 0.01mm

3. The best roughness on our wire cut EDM machine is less than1.0 um.

IV. Main specification

Parameters/ Model No. | TW040 | TW050 | TW063 | TW080 | TW100 |

X/Y Travel (mm) | 400*500 | 500*630 | 630*800 | 800*1000 | 1000*1200 |

Worktable (mm) | 490*790 | 570*920 | 690*1090 | 830*1290 | 1000*1600 |

Max cutting height (mm) | 500 | 500 | 500 | 500 | 500 |

Taper angle | A type:±3°/(Optional B type: ±30°) | ||||

Max cutting speed | 200 | ||||

Finish (one cutting) (um) | ≤2.5 | ||||

Finish (Multi cutting) (um) | ≤1.0 | ||||

Precision (mm) | ≤0.01 | ||||

Weight (kg) | 2000 | 2300 | 2800 | 3300 | 4000 |

Motor | Step Motors on X/Y axis (Servo motors are optional) | ||||

Machine size(cm) | 185*140*180 | 200*160*180 | 220*185*180 | 240*205*180 | 260*300*190 |

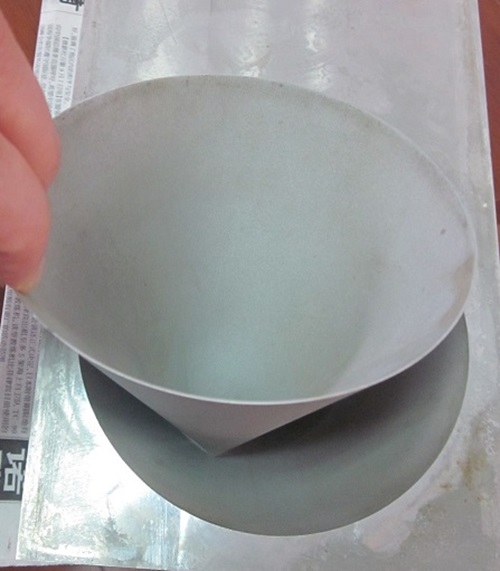

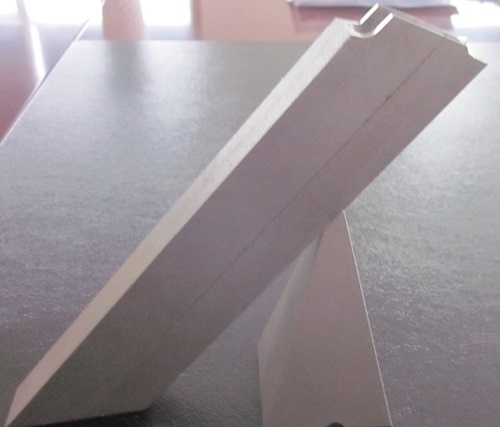

V. Pictures of our clients and workpieces:

INQUIRY

Categories

- CNC EDM Sawing Machines

- CNC Drilling EDM Machines

- CNC Wire EDM Machines

- CNC Sinker EDM Machines

- CNC Milling Engraving Machine

- CNC Diamond Wheel Dressers

- CNC Carbide Grinders

- CNC Electrochemical Deburring Machines

- Parts of CNC EDM Sawing Machines

- Parts of CNC Drilling EDM Machines

- Parts of CNC Wire EDM Machines

- Parts of CNC Sinker EDM Machines

- Parts of CNC Milling Engraving Machines

- Other Materials and Tools

Latest News

Contact Us

Contact: Mr.Bob Li

Phone: +86-13338697597

E-mail: sales@worthycnc.com

Whatsapp:+86-13338697597

Add: Room 301, Building 2, No. 38, Yaofeng Road, Jinqiao Development Zone, Mudu Town, Wuzhong District, Suzhou. PO: 215101