New Designed Wire Cut EDM Machine

New Designed Wire Cut EDM Machine

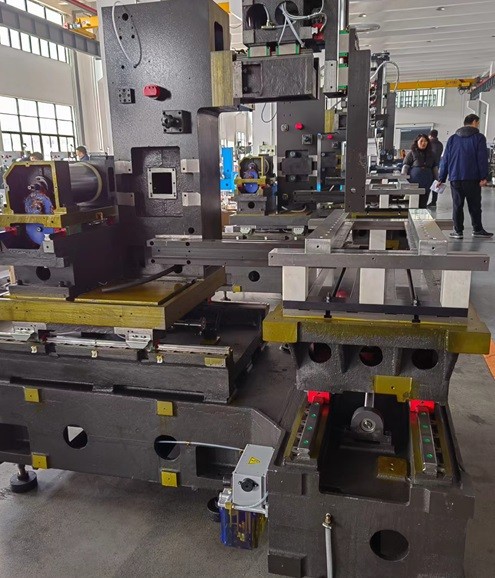

The wire cut EDM machine is new designed a water tank CNC lifting, high-precision large taper machining of the EDM wire-cutting machine, with seven-axis control.

It is a high precision multi-axis CNC WEDM machine with high reliability and high machining stability to realize the standard five-axis CNC four-axis linkage (optional turntable linkage) machining servo control mode.

It is a whole body using the "all in one" design, covers a smaller area and many other bright spots.

New Designed Wire Cut EDM Machine

I. Benefits of the latest wire cut EDM machine:

1. Ultra-low molybdenum wire loss; cutting 150,000 mm2 without wire broken;

2. Max cutting efficiency: over 300mm2 min

3. Best Surface roughness: Ras 0.5um

4. You can save more room with the all-in-one machine body and the water tank Auto lifting

II. Features of our latest wire cut EDM machine:

The wire cut EDM machine is new designed a water tank CNC lifting, high-precision large taper machining of the EDM wire-cutting machine, with seven-axis control.

It is a high precision multi-axis CNC WEDM machine with high reliability and high machining stability to realize the standard five-axis CNC four-axis linkage (optional turntable linkage) machining servo control mode. Machines is a whole body using the "all in one" design, covers a smaller area and many other bright spots.

III. Advantages:

1. Machinery

1)Through the finite element analysis and design, the long-term stability and reliability of the machine are greatly enhanced.

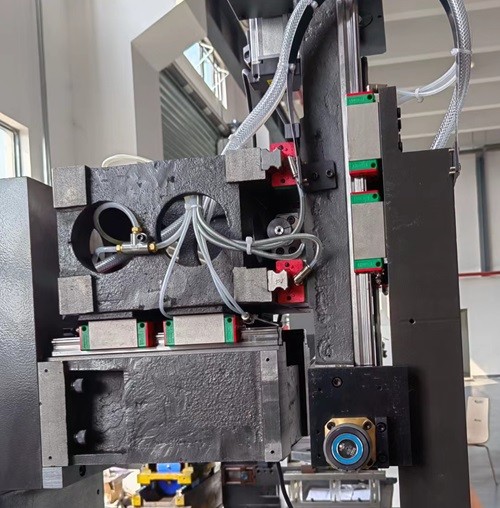

2)The liquid tank adopts electric automatic lifting, which makes the operator closer to the processing area and takes up less space.

3)The operating station can realize 90 degrees arbitrary rotation, compact structure, small footprint.

4)Anti-corrosion, anti-rust steel worktable, to ensure the worktable long-term use of high-precision.

5)It is manufactured in strict accordance with national standard (JBT11999.1-2014) and adopts Swiss GF manufacturing process, manufacturing standards and inspection standards.

6)Every step of the pursuit of "Fine work."

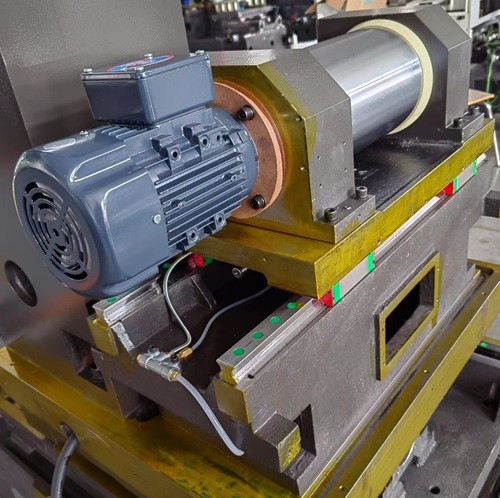

2. Drive and control

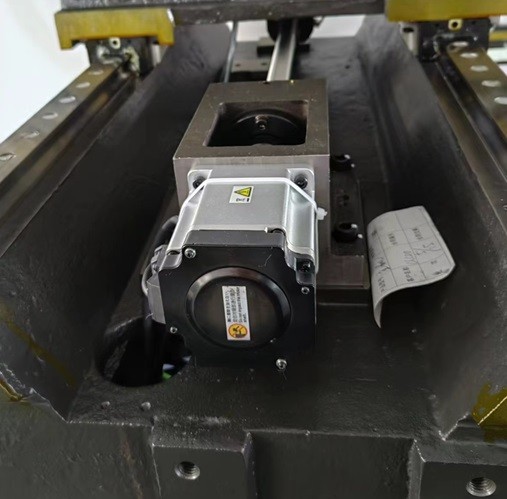

1)GF designed all imported linear guideway, ball screw and AC servo motor direct connection, higher accuracy, longer retention.

2) x, y, u, axes are controlled by imported AC servo motor and driver.

3) the U, V and Z axes are all controlled by double linear guide rails and ball screw to achieve the control precision of slow wire walking.

4) Five-axis CNC, control accuracy 0.001 mm.

5) all axes can realize pitch compensation and reverse clearance compensation, and realize high reliability and high precision of taper machining.

3. Wire movement

1)Constant tension control on wire structure, more convenient to the operator.

2) the parts of wire drum and transporting wire are all controlled by LED lamp lighting, which is convenient to operate.

4. Water tank filtration and environmental processing

1)Multi-stage filter water tank. Fully enclosed sheet metal design, and machine integration, greatly reducing the area.

2)Long-term processing without water spray, processing more health, more environmental protection.

5. Machining and inspection

1) High-precision imported gantry machining center, Precision Grinder and related precision equipment are used for high-precision machining of mechanical parts.

2) The wire cut EDM machine bed and its parts are inspected in strict accordance with the inspection standards of Swiss GF, using such testing equipment as German Zeiss coordinate measuring instrument, Japanese Sanfeng roughness measuring instrument, German height measuring instrument, etc.

3) The full range accuracy of the machine is measured and inspected by Renishaw laser interferometer, and the pitch and reverse clearance are compensated.

In order to better our product precision, consistency, and stability, we had imported Zeiss coordinate measuring instrument from Germany to test and check machine castings and purchased parts. We make sure you get the most out of it.

6. CNC system

1), With the national software copyright, international slow speed wire advanced motion algorithm, a new man-machine interface features, support G code operation.

2) the system adopts modularization, multi-CPU structure, sampling bus communication between modules, and the structure is more reasonable.

3) adopt international ISO code, better with the international standards, and the market mature WEDM programming software CAXA, tongda, Fix seamless docking, can better meet the needs of different programming habits of users.

4) the interpolation and servo tracking algorithms are optimized to improve the contour accuracy of the workpiece effectively.

5) the height of z axis can be obtained automatically, which can realize constant taper, variable taper, upper and lower special shape and other convenient taper machining, and the operation is convenient.

6) the angle between the workpiece and the coordinate system can be sensed and calculated automatically, and the "Automatic rotation" program can be selected by the system to compensate, thus greatly improving the workpiece clamping efficiency.

7) the system has abundant auxiliary functions, such as workpiece alignment, corner positioning, rotating mirror image, etc.

8) the system can choose the center of the circle or the center of the slot, or it can choose to find the center quickly along the direction of 0 degree or 45 degrees.

9) powerful auxiliary “specific Points" calculation function, through this tool can calculate and locate the midpoint of any two points, can calculate the angle of any two points and lines, can also calculate and locate the center of any three points, easy to operate.

10) According to customers’ needs, we can develop unique special features to improve your competitiveness.

11) NC power supply with adaptive control circuit to ensure that high current processing, not easy to break wire.

12) ultra-low molybdenum wire loss circuit.

13) CNC power supply with AC power supply control circuit, high-voltage, low-voltage circuit, fast access to processing Surface finish.

14) high-end machine body equipped with high-performance CNC power supply, not only can get high efficiency and ultra-low loss of molybdenum wire during roughing, but also can get the ultra-high finish in multi time cutting.

IV. Technical parameters of Wire EDM Machine

Type of equipment | Unit | TW-400 | |

| Size of machine (L × W × H) | mm | 1350*1720*2170 |

Total weight of equipment | kg | 2200 | |

Work table | Table size (width × length) | mm | 660*480 |

| X-axis | mm | 400 |

Y-axis | mm | 320 | |

Z- axis | mm | 300 | |

Working Fluid Tank | Length * width | mm | 1000*580 |

| Pulse width | us | 1-250 |

Ratio of output pulse gap to pulse width | 4—15 | ||

Number of low voltage tubes | 0-15 | ||

Number of high voltage tubes | 0-3 | ||

AC tube number | 0-3 | ||

AC pulse width | 0-7 | ||

Servo speed | 0-15 | ||

Servo tracking | 1-199 | ||

Servo speed limit | 1-500 | ||

Speed of wire running | 0-3 | ||

Cutting times | 1-7 | ||

Minimum mechanical equivalent of each axis | um | 1 | |

| Maximum cutting thickness | mm | 300 |

Maximum cutting taper/workpiece thickness | ±15°/80 | ||

Maximum worktable load | kg | 500 | |

| Positioning accuracy x/y | mm | ≤0.006 |

Repeated positioning accuracy x/y | mm | ≤0.003 | |

Multi-time cutting accuracy | mm | ≤0.005 (height 25mm, diameter 18, cutting three times, material SKD11 or CR12, HRC58) | |

Best Surface Roughness | um | Ra ≤0.5 (square 10mm * 10mm * 25mm trimming, material SKD11 or CR12, HRC58) | |

| Maximum cutting efficiency | mm2∕min | ≥300 |

Cutting efficiency in common use | mm2∕min | ≥180 | |

Maximum machining current | A | ≥12 | |

Consume power | KW | ≤2.3 | |

Wire running system | Diameter of electrode wire | mm | ∮0.12-∮0.2 |

Speed of wire drum | Frequency conversion speed regulation | ||

Tight wire Way | Electric automatic tensioner | ||

wire running speed | m/s | 3-12 | |

| Filtering accuracy | um | <10 |

Filter method | Multi-level filtering mode | ||

Working fluid | Eco-friendly cutting fluid | ||

| Electricity | 3 Ph 220/440v,60 Hz/ 2kVA | |

Temperature | Temperature 15-30°C/humidity 40-80% | ||

Barometric pressure | Kpa | 86-106kpa |

INQUIRY

Categories

- CNC EDM Sawing Machines

- CNC Drilling EDM Machines

- CNC Wire EDM Machines

- CNC Sinker EDM Machines

- CNC Milling Engraving Machine

- CNC Diamond Wheel Dressers

- CNC Carbide Grinders

- CNC Electrochemical Deburring Machines

- Parts of CNC EDM Sawing Machines

- Parts of CNC Drilling EDM Machines

- Parts of CNC Wire EDM Machines

- Parts of CNC Sinker EDM Machines

- Parts of CNC Milling Engraving Machines

- Other Materials and Tools

Latest News

Contact Us

Contact: Mr.Bob Li

Phone: +86-13338697597

E-mail: sales@worthycnc.com

Whatsapp:+86-13338697597

Add: Room 301, Building 2, No. 38, Yaofeng Road, Jinqiao Development Zone, Mudu Town, Wuzhong District, Suzhou. PO: 215101