CNC 6 axis Drilling EDM Machine

CNC 6 axis Drilling EDM Machine

CNC 6 axis Drilling EDM Machine is mainly used for drilling the air coolant holes on the aerospace engine blade .

CNC Drilling EDM machine

I. The benefits you can get with CNC Drilling EDM machine:

1. You can drill many holes on 3D complex jobs efficiently with a cardle type CNC turntable (B/C axis);

2. You can drill blind hole or through hole in a precision depth;

3. You can make 2D/3D model programming easily.

II. Usage field:

The 6 axis CNC drilling EDM machine can be used for drilling air holes of the turbine blade in aerospace industry.

III. The machine function:

1. Specialized in drilling turbine blade air holes

2. Minimum hole dia. ≤0.2mm

3. Cradle type table A, C axis

4. X, Y, Z, S, B, C axis can realize position closed-loop control

5. Any Angle air hole can be drilled with only once clamping

6. The hole penetration is judged automatically and the penetration depth is controllable

7. Patented technology taper hole processing, straight hole processing

8. Record of the drilling hole position data for traceability query

9. Multi-coordinate system international general G code programming

10. Pneumatic electrode handle ER chuck centering

11. Off-line electrode replacement

12. Remember the origin position at any time

13. Full system absolute encoder AC servo motor

14. Standard deionized water treatment system

15. The precision of the mechanical structure of the slide pillow is maintained for a long time.

16.On-line job measurement

17. Manual encoder shift shaft convenient and fast

IV. Advantages

1. It is composed of main engine, CNC pulse power control cabinet, deionized water treatment system, etc.

2. Main machine: composed of bed, column, X axis, Y axis, Z axis, S axis, B axis, C axis

3. CNC pulse power control cabinet: It is composed of industrial control computer, CNC system, touch screen, servo motors drive, machine tool electrical appliances, high-efficiency discharge pulse power supply, rocker arm waterproof and antipollution stainless steel keyboard control table, multi-function remote control hand box, etc.

4. Deionized water treatment systems: the 400 L stainless steel water tank, filter system, to ion system, conductivity detection system, high pressure water pump, etc.

V. Specification

Model | TD406CNC |

Work table size | 550×360mm |

Table travel(X×Y*Z) | 400×300*370mm |

S axis travel | 400 mm |

B axis rotation Angle | ±90° |

C axis rotation Angle | 0-360° |

C axis rotation table diameter | 250mm |

C axis rotation table load | ≤30kg |

Max distance between worktable to electrode chuck | 400mm |

Electrode diameter | 0.15-3.0 mm |

Electrode chuck | Pneumatic spring chuck |

Max moving speed of straight axis | ≥2000mm/min |

Motors of axis | Japan Panasonic/Fuji AC servo motor (absolute encoder) |

Min moving equivalent | 0.001mm |

Axis movement control mode | Multifunctional electronic hand wheel |

Input/output interface | USB 、LAN、RS-232 |

Control type | Industrial computer control card |

Screen | 15″LCD touch-screen |

Programming mode | G code, MDI, CAD list |

Pitch compensation | Yes |

Positioning accuracy | 0.010mm |

Repeated positioning accuracy | 0.005mm |

Working fluid pressure | 0-10Mpa |

Type of working fluid | Deionized water |

Compressed air pressure | 0.55~0.65MPa |

Max. working current | 30 A |

Max. drilling speed | 30 -120mm/min |

Machine dimension | 2300×2100×2500 mm |

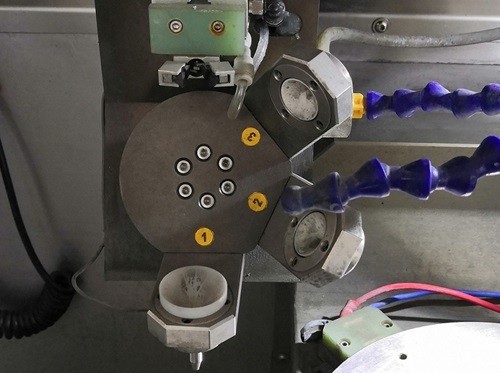

VI. Pictures of Drilling EDM machine samples:

INQUIRY

Categories

- CNC EDM Sawing Machines

- CNC Drilling EDM Machines

- CNC Wire EDM Machines

- CNC Sinker EDM Machines

- CNC Milling Engraving Machine

- CNC Diamond Wheel Dressers

- CNC Carbide Grinders

- CNC Electrochemical Deburring Machines

- Parts of CNC EDM Sawing Machines

- Parts of CNC Drilling EDM Machines

- Parts of CNC Wire EDM Machines

- Parts of CNC Sinker EDM Machines

- Parts of CNC Milling Engraving Machines

- Other Materials and Tools

Latest News

Contact Us

Contact: Mr.Bob Li

Phone: +86-13338697597

E-mail: sales@worthycnc.com

Whatsapp:+86-13338697597

Add: Room 301, Building 2, No. 38, Yaofeng Road, Jinqiao Development Zone, Mudu Town, Wuzhong District, Suzhou. PO: 215101